In recent years, major advancements have taken 3D printing from a complicated, novelty process to a viable production solution for manufacturers and consumers alike. 3D-printed objects can now be lighter, stronger, and more complex than those produced through traditional manufacturing. The equipment, processes, and materials continue to evolve. 3D printing is now taking its biggest leap forward with AI and machine vision integration.

In recent years, major advancements have taken 3D printing from a complicated, novelty process to a viable production solution for manufacturers and consumers alike. 3D-printed objects can now be lighter, stronger, and more complex than those produced through traditional manufacturing. The equipment, processes, and materials continue to evolve. 3D printing is now taking its biggest leap forward with AI and machine vision integration.

Artificial Intelligence and Machine Vision Enhance 3D Printing

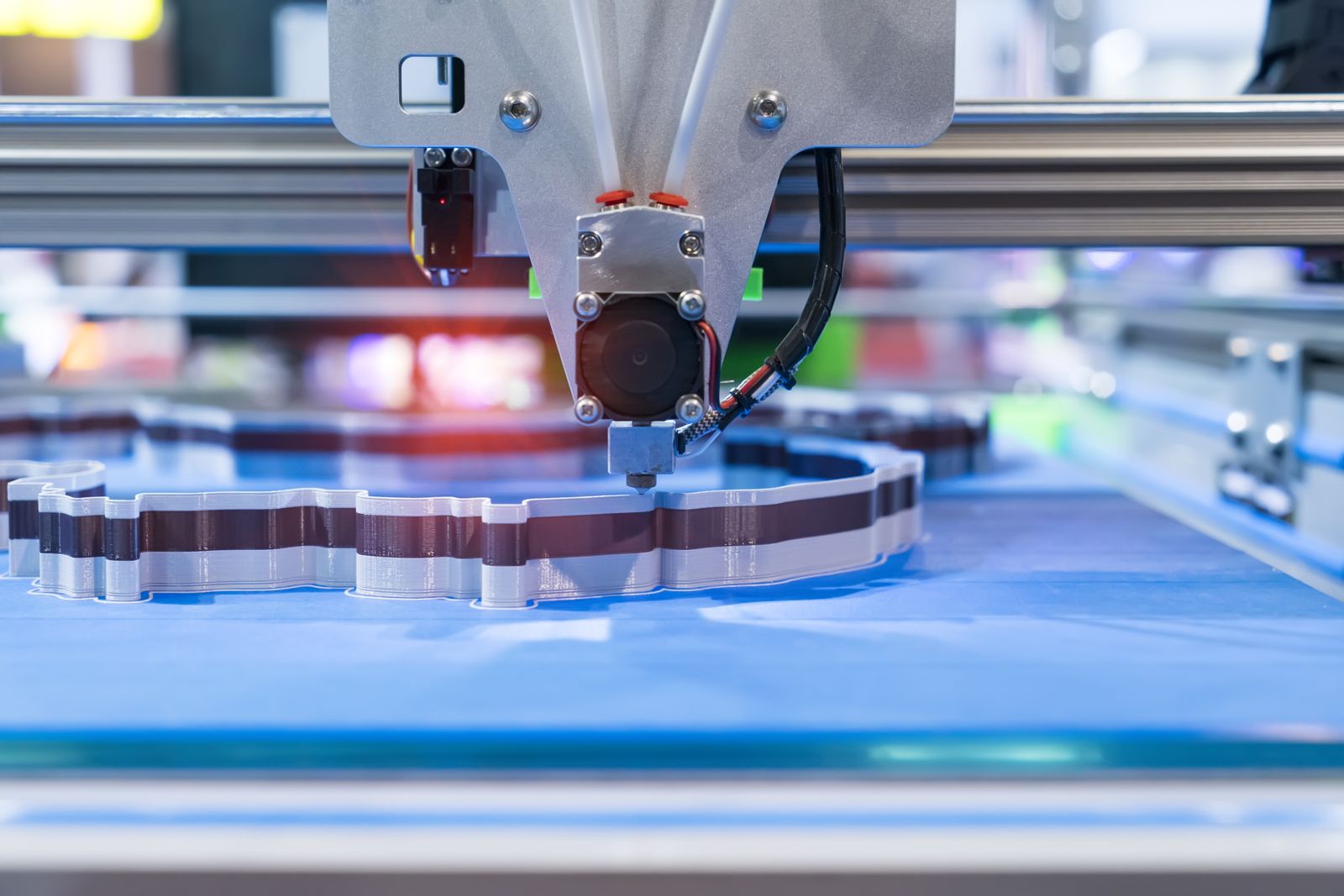

3D printing starts with a three-dimensional object in a CAD or digital 3D model. A computer-controlled system uses materials, often in liquid or powder form, to build a three-dimensional object layer by layer. In the past, it was mainly used to create prototypes quickly. One major advantage of 3D printing is the ability to produce very complex shapes impossible to build by hand, including hollow parts or parts with internal truss structures.

Manufacturers have long had to choose between high speed, high precision, or high-quality materials when selecting 3D printing methods. Few models of 3D printers could offer all three. But integration with artificial intelligence and machine vision make it possible. Artificial intelligence uses complex algorithms and massive amounts of data to endow the printer with the ability to make decisions that would ordinarily require human involvement.

Machine vision gives artificial intelligence the ability to “see” what it’s doing, boosting the 3D printer’s capabilities even further. The vision system scans each layer of an object being printed in vivid detail. The information collected is interpreted by the printer’s artificial intelligence system to predict warping behavior, decide what changes to make to the printing process, and deliver a higher quality product.

The Future of 3D Printing, AI & Machine Vision

The advantages of 3D printing are already obvious to manufacturers at this time. But adding the ability to learn the properties of a material and predict its behavior on the fly is sure to boost the demand for 3D printing. Manufacturers may soon be able to print objects using materials they never thought possible.

Printing with rubber-like materials like silicone or high-temperature materials such as epoxy can be difficult or impossible with today’s 3D printers. This limitation makes it difficult to use 3D printing for the insulation of electronics. But artificial intelligence and machine vision will soon allow manufacturers to leverage 3D printing in these applications.

Would you like to add machine vision to your 3D printing system? Then contact the vision experts at Phase 1 Technology Corp. and request information about which camera components or sensors are best for your 3D printing application.