Manufacturers are increasingly evaluating CMOS sensors for applications that once exclusively required the capabilities of the more costly CCD sensors. Due to their cost-effectiveness and growing capabilities, CMOS sensors are quickly becoming the preferred choice of machine vision camera manufacturers.

Manufacturers are increasingly evaluating CMOS sensors for applications that once exclusively required the capabilities of the more costly CCD sensors. Due to their cost-effectiveness and growing capabilities, CMOS sensors are quickly becoming the preferred choice of machine vision camera manufacturers.

What’s the Difference Between CCD and CMOS?

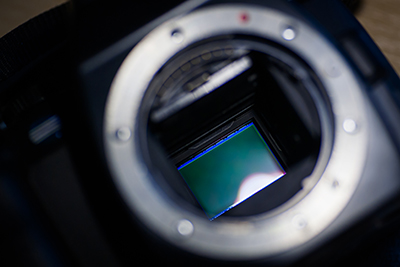

A CMOS sensor is a digital device. CMOS stands for ‘complementary metal-oxide semiconductor.’ A CMOS sensor converts the charge from a photosensitive pixel to a voltage at the pixel site. The signal is then multiplexed by row and column to multiple on-chip, digital-to-analog converters. CMOS sensors have high speed, low sensitivity, and high, fixed-pattern noise.

A CCD sensor is a “charged coupled device.” Just like a CMOS sensor, it converts light into electrons. Unlike a CMOS sensor, it is an analog device. It is a silicon chip that contains an array of photosensitive sites. Being an analog device, output is immediately converted to a digital signal by an analog-to-digital converter. The voltage is read from each site to reconstruct an image.

For a long time, the CCD sensor was the prevalent technology for capturing high-quality, low-noise images. But CCD sensors are expensive to manufacture, so they often come with a higher price tag. They also consume more power than CMOS sensors, sometimes a hundred times more. Luckily, CMOS sensor technology has advanced to the point where it is fast approaching the quality and capabilities of CCD technology, and with a significantly lower price tag, smaller size, and power consumption.

CMOS Sensors Are a Good Fit for Machine Vision

Modern cameras have decreased in size thanks to the growing capabilities of the CMOS sensor. Featuring previously unheard-of resolutions, low-light sensitivity, on-pixel innovations, and RGB-NIR color filter array options, CMOS sensors are taking the place of CCD for the manufacture of cameras and imaging solutions for the majority of industrial, medical and scientific applications.

CMOS cameras can have higher framerates than their CCD counterparts. This is because the reading of the pixels can be done faster than having to wait for a CCD’s charge transfer. This feature is essential for machine vision systems that often rely on real-time image processing for automation or image data analysis.

The way CMOS and CCD sensors respond to infrared wavelengths is also important for machine vision systems. CMOS sensors are more sensitive to IR wavelengths than CCD sensors. CMOS chip and camera manufacturers have used this advantage to capture IR light and provide additional imaging capabilities for image recognition.

Innovations and the Future of CMOS Sensors

Canon is leading the way with some of the most exciting CMOS sensor innovations at the pixel level. Canon’s 2U250MRXS CMOS sensor, for example, features an unprecedented 250 MP resolution capable of capturing detail 125 times greater than in full HD. This APS-H format sensor leverages a square pixel arrangement of 1.5µm x 1.5µm pixels, achieving ultra-high resolution in a compact design for use in a wide range of applications.

New to the industrial market, Canon offers several high-performance CMOS sensors. Among these is the 35MMFHDXS_A CMOS sensor featuring an enormous 19 µm pixels, which minimize noise and dark current and allow control over readout position and frame rate. The Canon 120MXS CMOS sensor delivers ultra-high 120 MP resolution in a compact design by incorporating close to the same number of pixels as photoreceptors in the human eye. Then there’s Canon’s 3U5MGXSBA Global Shutter 5 MP CMOS sensor, which offers fast, distortion-free image capture in a 2/3″ format, lower power consumption, and enhanced sensitivity.

RGB-NIR (Near Infrared) pixel filter options are available. Canon replaced one of the green filters on the sensor with an NIR filter, which gives the sensors the ability to “see” outside the visible spectrum and enables machine vision systems to classify images on another level.

With innovations such as Canon’s, CMOS sensors will be a key part of the future of machine vision. Expanded applications, such as driver assistance systems, lending vision to advanced machine learning algorithms, and enhancing the function of augmented reality, are possible thanks to the CMOS sensor’s growing capabilities, compact size, and lower costs.

For information about the possibilities of Canon CMOS sensors for your application, speak with an industrial imaging expert at Phase 1 Technology. Ask about an Evaluation Kit to test the unique capabilities of CMOS sensors from Canon.