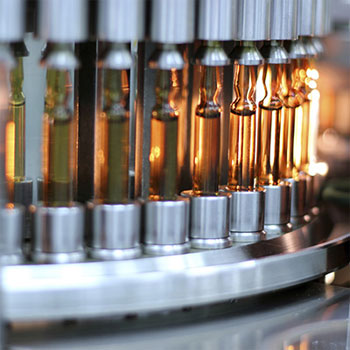

Through continuing innovation, machine vision systems have blazed the trail for faster, continuous, and more effective imaging. Accordingly, they have ensured increasingly simple and accurate identification of issues otherwise invisible to the human eye. In the process, flaw detection has remained central to machine vision and quality control.

Detecting Differences

At base, these systems use cameras and imaging sensors to detect imperfections, including line scan, area scan, extended spectrum, and smart cameras, as well as high-speed framegrabbers and X-ray detector panels. These are designed to function effectively at high speeds, high resolutions, and in standard and more challenging environments. Vision processors and software then use algorithms to check for changes in color, texture, and other patterns. In locating and identifying important features, this software makes it possible to align ideal and actual images in order to test for differences through counting, surface flaw detection, and other tools.

Trail-Blazing Methods

Since flaws vary in shape, size, and location, there are many methods for finding them. Traditional imaging tools help find clearly-defined errors, while advanced tools address textured surfaces or changing shapes and sizes by suppressing background noise. Flaws with no clear pattern, though, require more advanced tools like the following that identify errors by comparing actual and ideal products.

- Image differencing subtracts the ideal sample's image from that of the actual object to ensure similarity, with large differences leading to rejection.

- Pattern matching trains a vision system to observe and locate an ideal iteration of a pattern within an image to discover smaller defects.

Both these and other tools require careful lighting, the right lens, and alignment to ensure accuracy and prevent the consideration of changes in rotation, translation, or scale as defects. In detecting and resolving defects, machine vision systems help minimize such issues for manufacturing and other applications in order to keep those processes on track. Accordingly, they are essential not only to finding cracks, gaps, blemishes, and other flaws, but also to maintaining overall quality control.