When the machine vision industry first started out, frame grabbers became an indispensable technology. With the introduction of innovative high-resolution Canon CMOS sensor technology, they are now more important than ever.

When the machine vision industry first started out, frame grabbers became an indispensable technology. With the introduction of innovative high-resolution Canon CMOS sensor technology, they are now more important than ever.

Due to the growing demand for faster production and improved quality, frame grabbers are being leveraged along with high-resolution CMOS sensors for critical machine vision inspection applications such as electronics and flat-panel displays.

Why Use Frame Grabbers

Frame grabbers capture high-resolution images that aren’t possible with the use of a PC only or other solutions, such as integrated microprocessors. Modern frame grabbers are also capable of capturing multiple inputs simultaneously, transforming images when needed, and compressing image data to save cost and time on storage and data transfer.

New CMOS Sensors Need Frame Grabbers

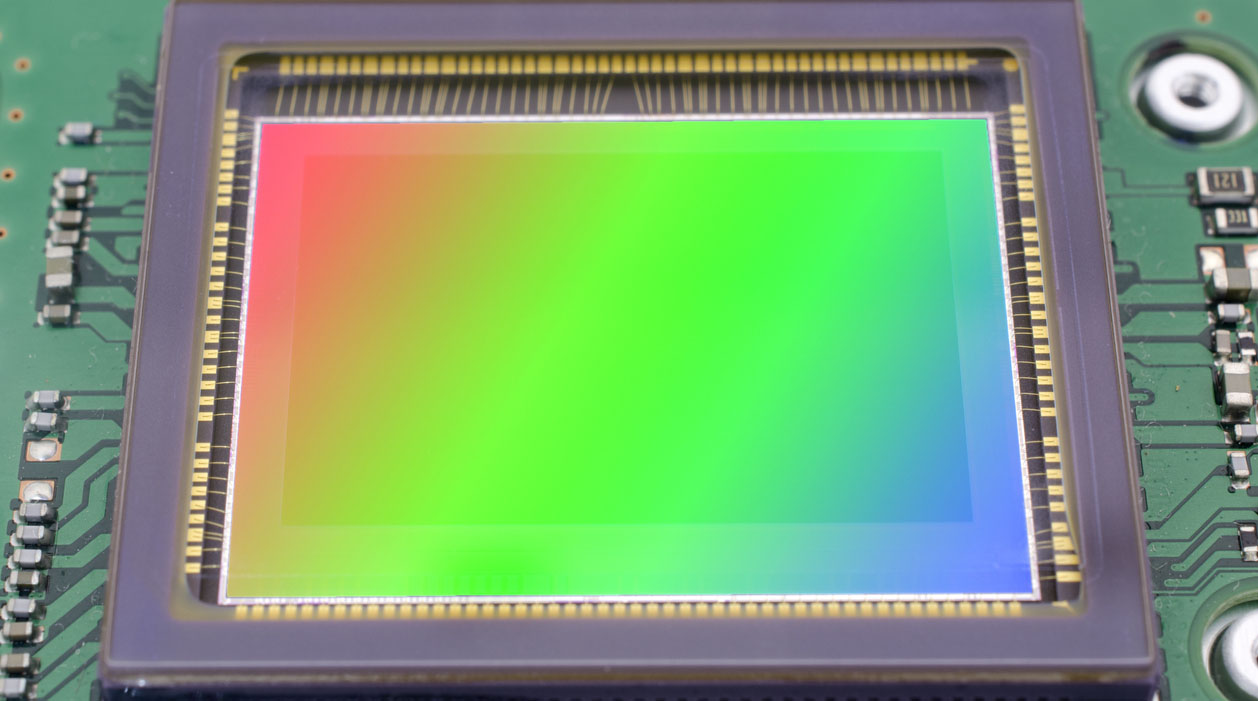

CMOS image sensors continue to increase in resolution and speed. 50-megapixel image sensors are common now, and Canon’s new 120MXS CMOS sensor delivers an ultra-high 120-megapixel resolution, which is setting a new standard for machine vision. The frame grabber enables the high-speed image capture of high-resolution images.

With such large amounts of image data being transferred, processed, and often compressed, data integrity is at risk. Some cables, protocols, and interfaces are susceptible to data loss. Frame grabbers help to improve reliable data transfer, reduce interrupt issues, and lessen the delays associated with high-speed, high-resolution image capture.

Application of Frame Grabbers in Machine Vision

Frame Grabbers are especially useful for the inspection of flat panel displays. Flat panel manufacturers are challenged with growing consumer demand and increased pressure to reduce costs. This leaves them looking for ways to improve production speed and efficiency.

Flat panel inspection is often viewed as a major bottleneck in the manufacturing process, limited by vision system capabilities. But Canon’s new line of industrial CMOS sensors is changing that. And frame grabbers are essential to those sensors.

Canon’s CMOS sensors have achieved groundbreaking resolution, frame rates, and sensitivity. These new sensors are capable of detecting minute defects in flat panel displays. They can be used to discover issues like nonuniform brightness, pixel defects, dead columns, and luminance mura (varying lightness and darkness compared to the average value of the display). They can also be used to find issues with pure glass displays, backlights, and color filters. With such high resolution capabilities, frame grabbers are a necessity. Canon says they already have a 250-megapixel CMOS sensor in the works.

For more information about high-speed, high-resolution CMOS image sensors for your applications, speak with the machine vision experts at Phase 1 Technology.