Sony is the world leader in image sensing technology, which drives today’s vision systems. From imagers that make Formula One race cars look like they’re standing still to ones that can make night look like day, Sony attains the highest standards of accuracy and performance. With Sony sensors, not only will your system perform better within your specific application, it will exceed all your expectations.

Like any other product in the marketplace, image sensors for vision systems have become specialized to maximize performance for certain applications. The Sony STARVIS and Pregius CMOS vision sensors are two of those optimized products. The STARVIS line falls predominantly into the Drone and Surveillance realm for Sony, while the Pregius line falls into the Industrial sector. Both have similar, excellent performance features while each has their own unique characteristics, creating sensors that perform in certain conditions at a level unmatched by others.

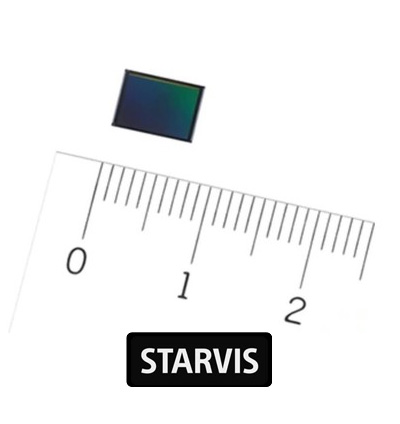

Sony STARVIS Sensor

The Sony STARVIS sensors are part of a line of products that are optimized for video streaming applications (though it is utilized in a variety of industrial applications as well). When you think surveillance, the first thing that comes to mind is a system that requires the ability to “see” everywhere, all the time. Sony STARVIS sensors allows your system to see more - in a wider range of conditions - than previous sensors. Back-illuminated pixel technology, combined with pixels specifically developed for high resolution applications are enhanced by the use of this technology. Along with testing regimens that quantitatively qualify sensors based on a set of standard requirements, which gives this sensor line, superior image quality from low light to high contrast. The technology allows for Near Infrared image capturing, turning night into day, allowing you to see into those dark corners where the monsters like to lurk. HDR technology takes locations with lighting “hot spots” and compensates for them, creating a system that is no longer blinded by the light, but lets you see the entire scene accurately and effectively.

The Sony STARVIS sensors are part of a line of products that are optimized for video streaming applications (though it is utilized in a variety of industrial applications as well). When you think surveillance, the first thing that comes to mind is a system that requires the ability to “see” everywhere, all the time. Sony STARVIS sensors allows your system to see more - in a wider range of conditions - than previous sensors. Back-illuminated pixel technology, combined with pixels specifically developed for high resolution applications are enhanced by the use of this technology. Along with testing regimens that quantitatively qualify sensors based on a set of standard requirements, which gives this sensor line, superior image quality from low light to high contrast. The technology allows for Near Infrared image capturing, turning night into day, allowing you to see into those dark corners where the monsters like to lurk. HDR technology takes locations with lighting “hot spots” and compensates for them, creating a system that is no longer blinded by the light, but lets you see the entire scene accurately and effectively.

These performance enhancements wouldn’t be achievable without the back-illuminated sensor structure. As the rearranging of the various layers that make up a sensor allow for more light from the viewed image to interact with the light-receiving surface. This improved image quality allows for more effective use of tools on the images, resulting in impressive picture quality. This technology allows the imager to capture many more electrons and ultimately a better image.

The SNR1(s) quality test is a tool that Sony uses to quantitatively determine their sensor performance. The testing involves the same parameters each time, allowing for engineers to not just say the sensor is “good enough” but to give each sensor a quality value that allows for comparison not only between sensors, but between iterations of each sensor. This also gives the engineering team the ability to introduce enhancements into the process, and see if these improvements had any unwanted side effects to any of the imager’s previously determined specifications. This allows them to control and monitor upgrades, while ensuring each iteration performs exactly as the previous generation.

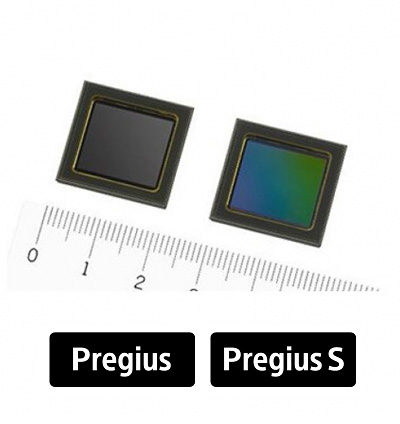

Sony Pregius Sensor

Sony Pregius Sensor

The Sony Pregius sensor is part of the Industrial line of products and is optimized for conditions seen in production lines and industrial processes. These conditions and requirements differ from the video streaming applications, and the sensor’s performance capabilities reflect that. Industrial applications tend to have more control over lighting conditions, so the ability to see in the dark like Surveillance products is not as necessary. Instead, industrial applications tend to have the challenge of requiring superior image quality with subjects moving at extremely high speeds. The Pregius sensors are specifically tuned for these applications and utilize several technologies to excel. Global Shutter technology and Active Pixel CMOS sensors create performance that allows for high-speed, high-precision images to be captured for industrial applications.

Global Shutter technology is essential for triggering a camera for specific events. Sony’s use of this technology in the Pregius sensors removes distortion from images of objects moving at high speed, creating a more accurate representation of the actual image. This reduction in distortion is important for machine vision applications, where high accuracy images of high-speed components is required. Pregius sensors allow machine vision systems to take a bottling line that is moving thousands of bottles per minute and create images as if the bottles were standing still. With quality requirements in products becoming more stringent every day, the ability to perform more accurate analysis during production allows manufacturers to reduce reaction times, increase response quality, and reduce lost production and waste.

Certain Pregius imagers also utilize a back-illuminated sensor in addition to Active Pixel CMOS technology, creating higher quality images at faster framerates than their front-illuminated brethren. The back-illumination technology is one of the keys to Sony’s excellent image quality. With chips tuned for high speed capture, this technology shines in its ability to efficiently transfer images, improving capture speed.

The Sony Pregius and STARVIS sensor lines are both peak performers in their families and have different characteristics allowing them to excel in different areas. Thinking beyond the product line, the capabilities of these sensors allow them to be used in the development of new and emerging products and technologies.

Need a vision system to monitor production quality at the exit of a blast furnace? The HDR and Near Infrared capabilities of the STARVIS will allow you to capture more consistent images even though the contrast between the bright furnace exit and the darkened furnace room make other systems useless.

Need to verify that company vehicles are being checked in and out properly, but the only location for tag identification is a high-speed road with a small window of opportunity for image capture? The Pregius sensors ability to take high quality images of high-speed components might be the answer to consistently and accurately scanning identification tags.

In the end, with the excellent overall performance and varied capabilities, speaking with someone who understands the capabilities of all the sensors and the best fit your requirements are important. Creating a superior image capture system is less daunting when you combine knowledgeable experts in each aspect of the system. When you want to find the right sensor for your application and create a system that will not just perform but excel at your application, the experts at Phase 1 can guide you to the right product.