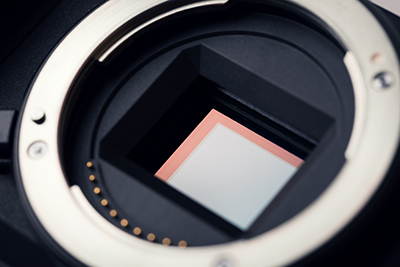

Sony’s global shutter Pregius CMOS sensors offer the fast frame rates of CMOS with CCD-like imaging performance. Sony’s inaugural Pregius sensor, the IMX174, was the first of its kind to offer a viable alternative to CCD sensors.

Sony’s global shutter Pregius CMOS sensors offer the fast frame rates of CMOS with CCD-like imaging performance. Sony’s inaugural Pregius sensor, the IMX174, was the first of its kind to offer a viable alternative to CCD sensors.

The Pregius sensor changed the technology landscape with the introduction of global shutter. Global shutter has the ability to start and stop light exposure time for all pixels simultaneously, which is ideally suited to imaging fast-moving objects. CMOS sensor technologies continue to grow with further advances in resolution, frame rate, sensitivity, readout-noise, high-dynamic range, and control features that enable new applications in industrial imaging.

The Secret Behind Sony’s Exmor Technology

One could say that Sony’s Exmor technology is the secret behind the outstanding performance of the Pregius CMOS sensors. A key to Exmor technology is the digitization of the pixel data early in the transfer process. As a result, the amount of additional noise accumulated as the image data travels around within the sensor is minimized, even at high speed.

Sony further improves the noise response of the sensor through correlated double sampling on either side of the analog-to-digital conversion. This cancels out the noise in the signals and ensures the accuracy of the digitized data.

The Evolution of Each Pregius Generation

Throughout its evolution, Sony’s Pregius CMOS sensor line continued to feature basically the same pixel and readout circuit architecture. Although each new generation brought enhancements over the previous one, improvements came with trade-offs in pixel size, saturation capacity, and sensor size. Essentially, the application dictates the generation of Pregius that can be used.

Sony’s first-generation had a 2.4 MP resolution with 5.86μm pixels and a well depth of 30Ke-. This game-changing design allowed for vision applications with an image quality and speed that was impossible for CCD technology.

The second generation of the Pregius took the CMOS sensor to 12 MP image resolution. But pixel size decreased to 3.45μm pixels and a well depth of 10Ke-. As an added benefit, noise also decreased. This great family of image sensors turned out a large number of machine vision industrial cameras at a lower cost than CCDs and with better performance. Thanks to the pixel size, the sensor is a direct replacement to some CCD sensors, easily turning a CCD system into CMOS.

Generation 3 has taken the best of both worlds. Pixel size has increased to 4.5μm and increased the well depth to 20Ke-. A host of helpful functions enable simpler and more powerful vision systems. A self-trigger mode allows two regions of interest (ROI) to be set. One ROI is used for image capture and the other is used to trigger the capture. Dual trigger mode lets the sensor have two different levels of exposure and gain. This lets one camera take one image that contains two separate sensor configurations.

Offering performance, design and cost benefits, Sony Pregius CMOS sensors are a good replacement for CCD for a wide variety of machine vision applications.

To discuss Sony Pregius CMOS sensors for your applications, contact the machine vision camera and component experts at Phase 1 Technology.

You may also wish to read: Why Sony Pregius Global Shutter CMOS Sensors Lead the Pack.