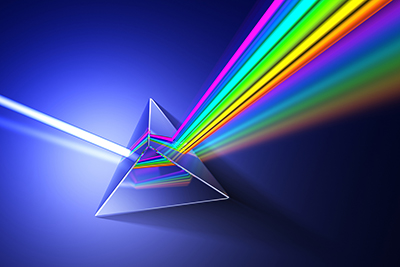

The human eye is a marvel. Mankind has used this complex sensor to inspect objects with visible light since arriving on the world scene. Visible light cameras let humans mimic the eye and record the data it captures. But the discovery of the electromagnetic spectrum has led to camera technologies that, in many ways, exceed the capabilities of the human eye. And industries are turning to hyperspectral imaging to go beyond where the eye has taken us.

Hyperspectral Imaging Benefits Manufacturers

Aside from imaging techniques that capture visible light, there are many technologies that can detect information across the electromagnetic spectrum. But hyperspectral imaging uses a much larger range of light wavelengths and is also able to gather data more information per pixel on a given image.

Many spectral imaging systems can only capture color information on the red, blue, and green wavelengths. But hyperspectral imaging can capture hundreds of distinct “colors” that cannot be seen with the human eye. This capability can help manufacturers find material defects or inconsistencies both on an object’s surface and lurking underneath.

Industries Adopting Hyperspectral Imaging

Because hyperspectral imaging can provide faster, more accurate results than human sorting, the interest of a number of industries has boosted its popularity. The more-efficient sorting process turns out to be less expensive and boosts quality control measurements for industries that can make use of this cutting-edge imaging technology.

Pharmaceutical Industry. Pills might look the same to the eye. But impurities and defects can affect their safety and efficacy. Hyperspectral systems quickly find bad pills and remove them from the lot. Such precision is essential for such a highly-regulated industry.

Food Production. Many of the contaminants present in food are hard to tell apart from the product itself. For example, maggots can be found in rice. Other foods like sausages are highly processed and contamination can go unnoticed, but not with hyperspectral imaging. The thin margins of food production make this recall-prevention technology even more important.

Construction Materials. Hyperspectral imaging isn’t just useful for consumable products. Construction materials can be inspected in advance to ensure integrity. For example, damp spots, knotholes, and resin pockets can be found in wood to be used on a project. Materials like plastics are hard to tell apart. But hyperspectral imaging makes this task a breeze to complete.

Medical Applications. Physicians have been using the electromagnetic spectrum to find signs of disease for decades. Hyperspectral imaging offers an alternative to X-rays, CAT scans, and MRIs when looking for diseases like cancer.

Want to find out how hyperspectral imaging can help your industrial process? Contact Phase 1 and ask about the latest in machine vision and industrial cameras.