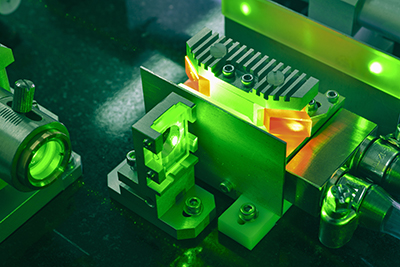

Machine vision lighting systems are crucial to the proper function of vision systems. The human eye can adjust rapidly and see well in an astonishingly wide range of conditions. The technology created for machine vision systems used for industrial inspection is incredibly advanced, but it still can’t “see” as well as the human eye. Therefore, proper lighting must be provided for machine vision systems.

Machine vision lighting systems are crucial to the proper function of vision systems. The human eye can adjust rapidly and see well in an astonishingly wide range of conditions. The technology created for machine vision systems used for industrial inspection is incredibly advanced, but it still can’t “see” as well as the human eye. Therefore, proper lighting must be provided for machine vision systems.

Machine Vision Lighting Considerations

Machine vision lighting must be regulated and constant. If the light changes, the industrial inspection system may misinterpret the change as a change to the product itself. Machine vision lighting should amplify the elements of the parts that are to be inspected. It should also reduce the elements that are not to be considered for inspection.

Good machine vision lighting makes industrial inspection go faster and increases accuracy. Poor lighting often results in faults and failure. Most of the time, existing lighting is not good enough for machine vision. If overhead lights dim or burn out, the machine vision system may report errors on the production line. Therefore, it’s important to install a dedicated machine vision lighting system.

Types of Machine Vision Lighting

Since lighting is so crucial to machine vision and industrial inspection, a large variety of options are available to ensure that vision systems have the optimal lighting available for their application. Here are just some of the available lighting options.

Backlighting

Backlighting provides an even illumination from behind the object being inspected. This highlights the silhouette of the object. Backlighting allows industrial inspection of holes, object outlines, and scratches on clear parts. Backlighting does not allow for inspection of surface detail.

Dark Field Lighting

Darkfield lighting is a useful process for detecting surface features. This technique provides a light at a shallow angle to the object ready for inspection. Scratches, edges, and notches shine brightly while the remainder of the object’s surface is dark. Any directional light that can be angled can be used.

Dome Lighting

If a uniform light is needed that eliminates glare, dome lighting offers light from various angles without glare, even on mirrored objects. Dome lighting is best for shiny, curved surfaces. Dome lighting must be mounted close to the object being inspected.

Low Angle Dark Field Lighting

This form of lighting shines on an object at a 10-15-degree angle. Surface features such as scuffs and fingerprints appear bright on a mirrored surface, while the rest of the surface remains dark. Height differences are also highlighted.

Ring Lighting

Ring Lighting illuminates the object’s surface with a circle of bright, intense lighting. It eliminates shadows and offers good contrast. But it can cause a glare on reflective parts. Ring lighting is common and can be used in a wide number of industrial inspection applications.

For help with your machine vision application, speak with a Phase 1 Technology machine vision lighting and industrial LED lighting controllers expert.